Magnet Neodymium Iron Boron (NdFeB) Sinter

Sinter Neodymium Iron Boron Magnet (Sintered NdFeB Magnet), sebagai bahan magnet tanah jarang yang paling kuat, telah memainkan peran yang sangat penting dalam beberapa aplikasi. Dengan sifat magnet permanen yang stabil dan sangat baik dan kemampuan mesin, ia dapat memasok magnet super kuat dengan ukuran yang sangat kecil.Bahan ini telah banyak digunakan di bidang-bidang seperti: komunikasi (Ponsel, komputer), transportasi (Otomotif), energi (pembangkit tenaga angin), mesin (Motor), peralatan rumah tangga (Kulkas, mesin cuci), medis (NMR), dll.

Sinter Neodymium Iron Boron Magnet (Sintered NdFeB Magnet), sebagai bahan magnet tanah jarang yang paling kuat, telah memainkan peran yang sangat penting dalam beberapa aplikasi. Dengan sifat magnet permanen yang stabil dan sangat baik dan kemampuan mesin, ia dapat memasok magnet super kuat dengan ukuran yang sangat kecil.Bahan ini telah banyak digunakan di bidang-bidang seperti: komunikasi (Ponsel, komputer), transportasi (Otomotif), energi (pembangkit tenaga angin), mesin (Motor), peralatan rumah tangga (Kulkas, mesin cuci), medis (NMR), dll.

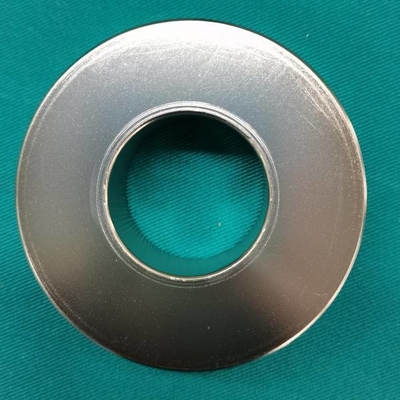

Perusahaan kami dapat menyediakan magnet NdFeB yang disinter dalam kotak, silinder, cincin, lembaran, cincin berdinding tipis, ubin, bola dan bagian dengan bentuk yang kompleks.

Perusahaan kami dapat menyediakan magnet NdFeB yang disinter dalam kotak, silinder, cincin, lembaran, cincin berdinding tipis, ubin, bola dan bagian dengan bentuk yang kompleks.

Fitur

- Sifat magnet super kuat, dengan ukuran terkecil untuk mendapatkan daya magnet tertinggi;

- Maks.Bekerja temp.250 ;

- Kemampuan mesin yang andal dan stabil, diproses sebagai bagian akhir yang rumit dan presisi;

- Ketahanan korosi yang andal, berbagai pelapis (nikel, seng, epoksi, emas, perak, aluminium, parylene, Everlube, cat, fosfat, dll.) memastikan ketahanan korosi dan penampilan produk;

Proses Magnetik

Parameter Magnetik

|

QINGDAO MAGNET MAGNETIC MATERIAL CO., LTD.Magnet NdFeB Sinter

Parameter Kinerja

|

|

| Nilai |

Br(20℃) |

pemaksaan |

BH(maks)(20℃) |

Koefisien Suhu |

Kepadatan |

Suhu Kerja Maks. |

| br |

Hcj |

Hcb |

BH (maks)

MGOe |

T1-T2 |

TK(Br)

Referensi |

TK(Hcj)

Referensi |

Referensi |

Tmax

Referensi |

| T |

KG |

kA/m |

koe |

kA/m |

koe |

kJ/m³ |

MGOe |

|

/℃ |

/℃ |

g/cm |

|

|

| N35 |

1.18-1.24 |

11,8-12,4 |

955 |

12 |

860 |

10.8 |

263-295 |

33-37 |

20-80 |

-0,105 |

-0,75 |

7.45 |

80 |

176 |

| N38 |

1.23-1.28 |

12,3-12,8 |

955 |

12 |

899 |

11.3 |

287-310 |

36-39 |

7.45 |

80 |

176 |

| N40 |

1.26-1.31 |

12.6-13.1 |

955 |

12 |

915 |

11.5 |

302-326 |

38-41 |

7.45 |

80 |

176 |

| N42 |

1.29-1.34 |

12.9-13.4 |

955 |

12 |

915 |

11.5 |

318-350 |

40-44 |

7.50 |

80 |

176 |

| N45 |

1.33-1.38 |

13,3-13,8 |

955 |

12 |

915 |

11.5 |

342-366 |

43-46 |

7.50 |

80 |

176 |

| N48 |

1.37-1.41 |

13,7-14,1 |

955 |

12 |

915 |

11.5 |

358-382 |

45-48 |

7.55 |

80 |

176 |

| N50 |

1.39-1.43 |

13,9-14,3 |

955 |

12 |

915 |

11.5 |

374-398 |

47-50 |

7.55 |

80 |

176 |

| N52 |

1,42-1,47 |

14.2-14.7 |

955 |

12 |

915 |

11.5 |

390-414 |

49-52 |

7.60 |

80 |

176 |

| N54 |

1,45-1,50 |

14.5-14.0 |

876 |

11 |

836 |

10.5 |

406-430 |

51-54 |

7.60 |

80 |

176 |

| 35M |

1.18-1.24 |

11,8-12,4 |

1114 |

14 |

868 |

10.9 |

263-295 |

33-37 |

20-100 |

-0,105 |

-0,70 |

7.45 |

100 |

212 |

| 38M |

1.23-1.28 |

12,3-12,8 |

1114 |

14 |

907 |

11.4 |

287-310 |

36-39 |

7.45 |

100 |

212 |

| 40M |

1.26-1.31 |

12.6-13.1 |

1114 |

14 |

931 |

11.7 |

302-326 |

38-41 |

7.50 |

100 |

212 |

| 42M |

1.29-1.34 |

12.9-13.4 |

1114 |

14 |

955 |

12.0 |

318-350 |

40-44 |

7.50 |

100 |

212 |

| 45M |

1.33-1.38 |

13,3-13,8 |

1114 |

14 |

987 |

12.4 |

342-366 |

43-46 |

7.55 |

100 |

212 |

| 48M |

1.37-1.41 |

13,7-14,1 |

1114 |

14 |

1019 |

12.8 |

358-382 |

45-48 |

7.55 |

100 |

212 |

| 50M |

1.39-1.43 |

13,9-14,3 |

1114 |

14 |

1035 |

13.0 |

374-398 |

47-50 |

7.60 |

100 |

212 |

| 52M |

1,42-1,47 |

14.2-14.7 |

1114 |

14 |

1059 |

13.3 |

390-414 |

49-52 |

7.60 |

100 |

212 |

| 54M* |

1,45-1,50 |

14.5-14.0 |

1114 |

14 |

1075 |

13.5 |

406-430 |

51-54 |

7.60 |

100 |

212 |

| 35H |

1.18-1.24 |

11,8-12,4 |

1353 |

17 |

876 |

11.0 |

263-295 |

33-37 |

20-120 |

-0,105 |

-0,60 |

7.45 |

120 |

248 |

| 38H |

1.23-1.28 |

12,3-12,8 |

1353 |

17 |

915 |

11.5 |

287-310 |

36-39 |

7.45 |

120 |

248 |

| 40H |

1.26-1.31 |

12.6-13.1 |

1353 |

17 |

939 |

11.8 |

302-326 |

38-41 |

7.50 |

120 |

248 |

| 42H |

1.29-1.34 |

12.9-13.4 |

1353 |

17 |

963 |

12.1 |

318-350 |

40-44 |

7.50 |

120 |

248 |

| 45H |

1.33-1.38 |

13,3-13,8 |

1353 |

17 |

995 |

12.5 |

342-366 |

43-46 |

7.55 |

120 |

248 |

| 48H |

1.37-1.41 |

13,7-14,1 |

1274 |

16 |

1027 |

12.9 |

358-382 |

45-48 |

7.55 |

120 |

248 |

| 50H |

1.39-1.43 |

13,9-14,3 |

1274 |

16 |

1043 |

13.1 |

374-398 |

47-50 |

7.60 |

120 |

248 |

| 52H* |

1,42-1,47 |

14.2-14.7 |

1274 |

16 |

1067 |

13.4 |

390-414 |

49-52 |

7.60 |

120 |

248 |

| 35SH |

1.18-1.24 |

11,8-12,4 |

1592 |

20 |

884 |

11.1 |

263-295 |

33-37 |

20-150 |

-0,105 |

-0,55 |

7.50 |

150 |

302 |

| 38SH |

1.23-1.28 |

12,3-12,8 |

1592 |

20 |

923 |

11.6 |

287-310 |

36-39 |

7.50 |

150 |

302 |

| 40SH |

1.26-1.31 |

12.6-13.1 |

1592 |

20 |

947 |

11.9 |

302-326 |

38-41 |

7.55 |

150 |

302 |

| 42SH |

1.29-1.34 |

12.9-13.4 |

1592 |

20 |

971 |

12.0 |

318-350 |

40-44 |

7.55 |

150 |

302 |

| 45SH |

1.33-1.38 |

13,3-13,8 |

1592 |

20 |

1003 |

12.6 |

342-366 |

43-46 |

7.60 |

150 |

302 |

| 48SH |

1.37-1.41 |

13,7-14,1 |

1592 |

20 |

1035 |

13.0 |

358-382 |

45-48 |

7.60 |

150 |

302 |

| 50SH |

1.39-1.43 |

13,9-14,3 |

1592 |

20 |

1051 |

13.2 |

374-398 |

47-50 |

7.60 |

150 |

302 |

| 52SH* |

1,42-1,47 |

14.2-14.7 |

1592 |

20 |

1075 |

13.3 |

390-414 |

49-52 |

7.60 |

150 |

302 |

| 30UH |

1.08-1.15 |

10.8-11.5 |

1990 |

25 |

812 |

10.2 |

223-255 |

28-32 |

20-180 |

-0,115 |

-0,45 |

7.55 |

180 |

356 |

| 33UH |

1.14-1.19 |

11.4-11.9 |

1990 |

25 |

860 |

10.8 |

247-271 |

31-34 |

7.55 |

180 |

356 |

| 35UH |

1.18-1.24 |

11,8-12,4 |

1990 |

25 |

892 |

11.2 |

263-295 |

33-37 |

7.55 |

180 |

356 |

| 38UH |

1.23-1.28 |

12,3-12,8 |

1990 |

25 |

931 |

11.7 |

287-310 |

36-39 |

7.60 |

180 |

356 |

| 40UH |

1.26-1.31 |

12.6-13.1 |

1990 |

25 |

955 |

12.0 |

302-326 |

38-41 |

7.60 |

180 |

356 |

| 42UH |

1.29-1.34 |

12.9-13.4 |

1990 |

25 |

979 |

12.3 |

318-350 |

40-44 |

7.60 |

180 |

356 |

| 45UH |

1.33-1.38 |

13,3-13,8 |

1990 |

25 |

1011 |

12.7 |

342-366 |

43-46 |

7.60 |

180 |

356 |

| 48UH* |

1.36-1.40 |

13.6-14.0 |

1990 |

25 |

1035 |

13.0 |

358-382 |

45-48 |

7.60 |

180 |

356 |

| 50UH* |

1.38-1.42 |

13,8-14,2 |

1990 |

25 |

1051 |

13.2 |

374-398 |

47-50 |

7.60 |

180 |

356 |

| 30EH |

1.08-1.15 |

10.8-11.5 |

2388 |

30 |

820 |

10.3 |

223-255 |

28-32 |

20-200 |

-0,115 |

-0,45 |

7.55 |

200 |

392 |

| 33EH |

1.14-1.19 |

11.4-11.9 |

2388 |

30 |

868 |

10.9 |

247-271 |

31-34 |

7.55 |

200 |

392 |

| 35EH |

1.18-1.24 |

11,8-12,4 |

2388 |

30 |

899 |

11.3 |

263-295 |

33-37 |

7.6 |

200 |

392 |

| 38EH |

1.22-1.26 |

12.2-12.6 |

2388 |

30 |

931 |

11.7 |

287-310 |

36-39 |

7.6 |

200 |

392 |

| 40EH |

1,25-1,29 |

12.6-13.1 |

2388 |

30 |

955 |

12.0 |

302-326 |

38-41 |

7.65 |

200 |

392 |

| 42EH* |

1.28-1.32 |

12.8-13.2 |

2388 |

30 |

979 |

12.3 |

318-350 |

40-44 |

7.65 |

200 |

392 |

| 45EH* |

1.32-1.37 |

13,2-13.7 |

2388 |

30 |

1011 |

12.7 |

342-366 |

43-46 |

7.65 |

200 |

392 |

| 48EH* |

1.36-1.40 |

13.6-14.0 |

2388 |

30 |

1035 |

13.0 |

358-382 |

45-48 |

7.65 |

200 |

392 |

| 30TH |

1.08-1.15 |

10.8-11.5 |

2786 |

35 |

820 |

10.3 |

223-255 |

28-32 |

20-250 |

-0,115 |

-0,40 |

7.6 |

250 |

482 |

| 33TH |

1.14-1.19 |

11.4-11.9 |

2786 |

35 |

868 |

10.9 |

247-271 |

31-34 |

7.6 |

250 |

482 |

| 35EH |

1.18-1.24 |

11,8-12,4 |

2786 |

35 |

899 |

11.3 |

263-295 |

33-37 |

7.65 |

250 |

482 |

| 38EH |

1.22-1.26 |

12.2-12.6 |

2786 |

35 |

931 |

11.7 |

287-310 |

36-39 |

7.65 |

250 |

482 |

| 40EH* |

1,25-1,29 |

12.6-13.1 |

2786 |

35 |

955 |

12.0 |

302-326 |

38-41 |

7.65 |

250 |

482 |

| Catatan: Nilai dengan *ditandai menerapkan proses khusus. |

Pesan Anda harus antara 20-3.000 karakter!

Pesan Anda harus antara 20-3.000 karakter! Silakan periksa email Anda!

Silakan periksa email Anda!  Pesan Anda harus antara 20-3.000 karakter!

Pesan Anda harus antara 20-3.000 karakter! Silakan periksa email Anda!

Silakan periksa email Anda!